Capabilities

Advanced Custom Injection Molding Services

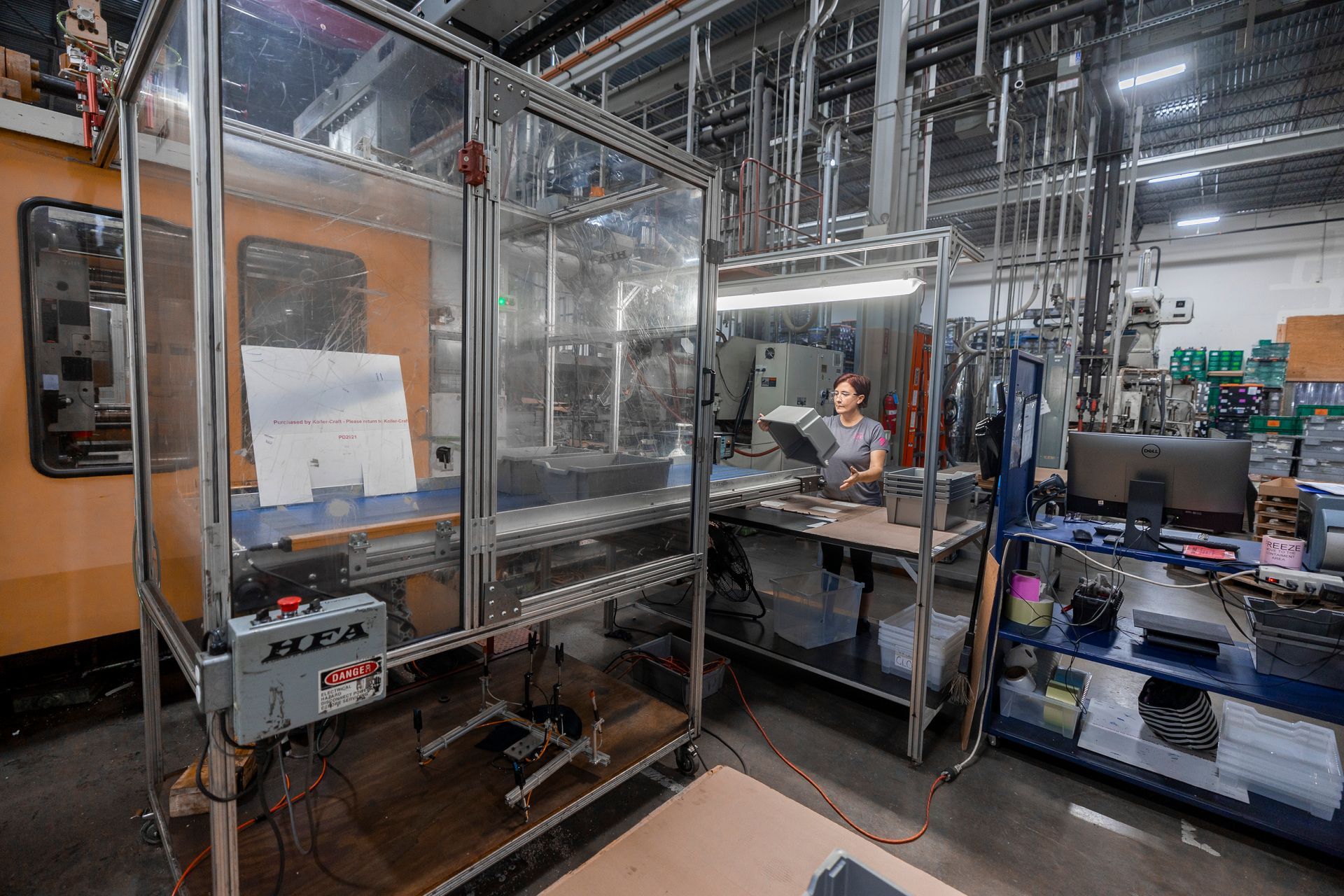

Koller Craft has over 80 years of experience providing high quality injection molded parts to a variety of industries. Our manufacturing team can provide a blend of management oversite and technical capability. We work closely with our customers to develop highly complex parts using the latest technology.

With a fleet of over 50 presses, spanning from 80 to 2200 tons, our capabilities are endless – from producing intricate, lightweight multicavity parts, to crafting sizable components weighing up to 22 pounds or measuring eight feet in length. This versatile range empowers us to handle entire assembly components, ensuring precise fit and function validation before they reach your assembly line or warehouse.

We have experience running many commodity thermoplastic materials such as PE and PP, as well as engineered resins such as PES, PC and PPO. Process control is used to optimize our molding processes, and robotics is used for part handling and assembly.

Injection Molding Techniques

Innovation is the key to staying ahead in manufacturing, and we are committed to utilizing and testing the latest techniques in injection molding. During the design process, our engineering team can assess whether additional methods would benefit the production of your custom part.

Gas Assist Injection Molding

Gas assist uses pressurized gas during the injection molding process to fill a mold while forming hollow sections of the part. It provides the ability to make parts like appliance or tool handles, or large, thick, ribbed parts, such as seats or structural elements.

Over Molding

This technique allows us to mold a second material over another component with different material properties. This allows us to create a single finished part with multiple materials, such as threaded inserts or fasteners, which may have variations in color, texture, or durability.

In-Mold Labeling

We seamlessly integrate labels directly into the injection molding process, resulting in a pristine, durable, and aesthetically pleasing finish.

Quick Links

Ready to Get Started?

Made in America

At Koller Craft, our commitment to excellence is matched only by our dedication to efficiency. By producing our high quality solutions right here in the USA, we can ensure quicker delivery times and rapid problem-solving.

FAQs

Have a question? We’re here to help.

Quality

Quality has been a founding principal of Koller Craft and remains a primary focus today. We are committed to having a world class quality system. We received our ISO 9001 certification in April 2003. We are continually evaluating our quality system to maintain our “edge.” As a Total Quality system, we employ many of the modern quality techniques and procedures that influence all aspects of our business.